Buildings

Though I had created a virtual Sketchup model of the layout at the beginning of the project, I had never been quite happy with the appearance of the buildings. To get the design right, I looked through as many photos as I could find of suitable industrial buildings, on various websites including the 28dayslater urban exploration forum. Unfortunately I can’t share any of them here due to copyright.

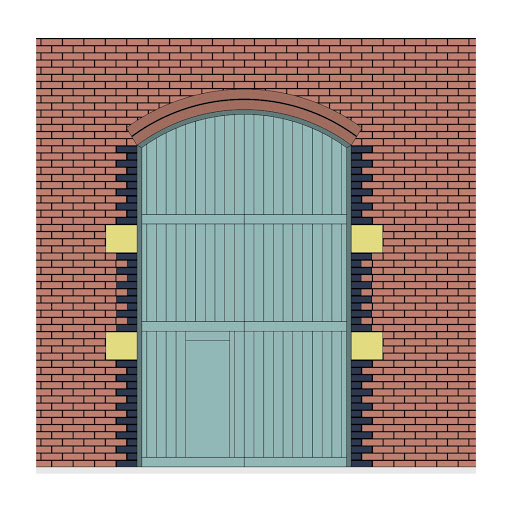

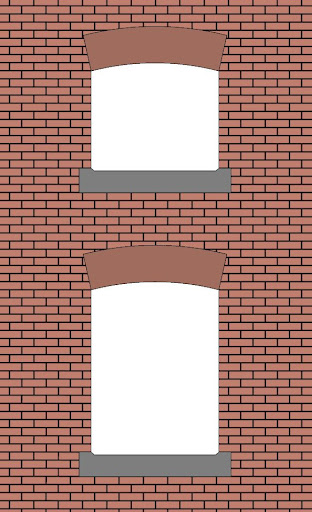

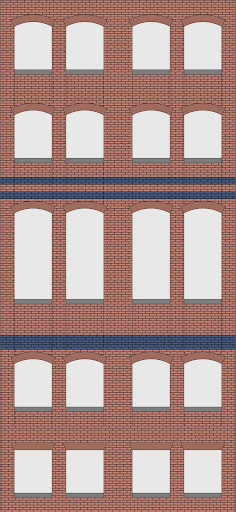

Working from the photos I’d found I used Sketchup to create scale drawings of elements of the buildings, especially the windows and doorways, approximating the dimensions by counting the bricks.

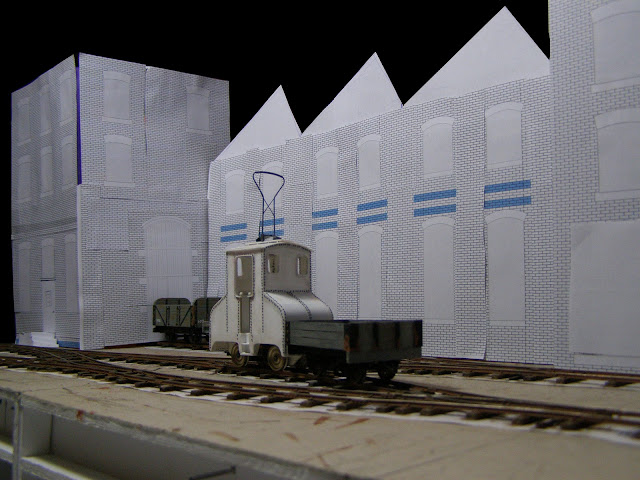

Once I’d drawn enough bits of buildings, I printed several copies of them out, used old cereal boxes to form the structure of the building, stuck the printouts on with double sided tape, a kept on putting them together and taking them apart until it all looked about right.

The real buildings are made from a foamboard core clad with Southeastern Finecast vacuum formed brick plastic. Construction started by drawing the design of the building onto a sheet of the plastic, ensuring the dimensions would all be whole numbers of bricks.

Next I cut out all the windows and doors…

…and stuck the plastic to a sheet of foamboard.

I used SE Finecast arches above the windows, and several layers of 2mm styrene for the window cills. Extra details were also styrene.

In a Christmas cracker I found some wooden golf tees, which I thought could be put to use as columns on the ground floor.

As I had no brass tube of suitable diameter, but plenty of pencils, I cut two suitable lengths from one, then cut off the top of two tees at the place where they were of the same diameter as the pencil. After filing the cut parts of both to get as smooth a join as possible, I superglued the parts together, then drilled a vertical hole through the top and inserted a piece of brass rod and some more glue to make the joint nice and strong. Brass rod was also inserted in the bottom to secure the column to the floor.

Finally I glued a square of styrene to the top, and wrapped a couple of bits of microstrip around the top and bottom of the capital to finish it off.

Decking for the platform, and the various doors, were made from balsa wood. So far I have also made a small bit of a building at the corner of the layout, and a bridge to connect the two together and provide a scenic break.

Painting the bricks was done according to the tried and tested method of painting everything brick coloured, then applying a wash of mortar colour and wiping off the excess. These last photos show the current state of the two buildings, now mostly complete but still requiring a bit of detailing and weathering, not to mention windows.